Quality Assurance system

Raiden’s quality assurance system is built on internationally recognized automotive standards, ensuring that every process meets the highest levels of reliability and safety. Each product family is supported by a clearly defined control and monitoring plan, covering every step from raw material approval to final inspection. By combining strict procedures, advanced technologies, and continuous improvement programs, Raiden guarantees that quality is safeguarded throughout the entire lifecycle of every part, from beginning to end.

Contact us

Raw Material & Supplier Approval

The process begins with the careful selection of suppliers and thorough verification of material documentation. All raw materials are checked for compliance with international standards and are inspected upon arrival through sampling. Every lot is fully traceable from receipt to final production, ensuring transparency and trust.

In Process Control

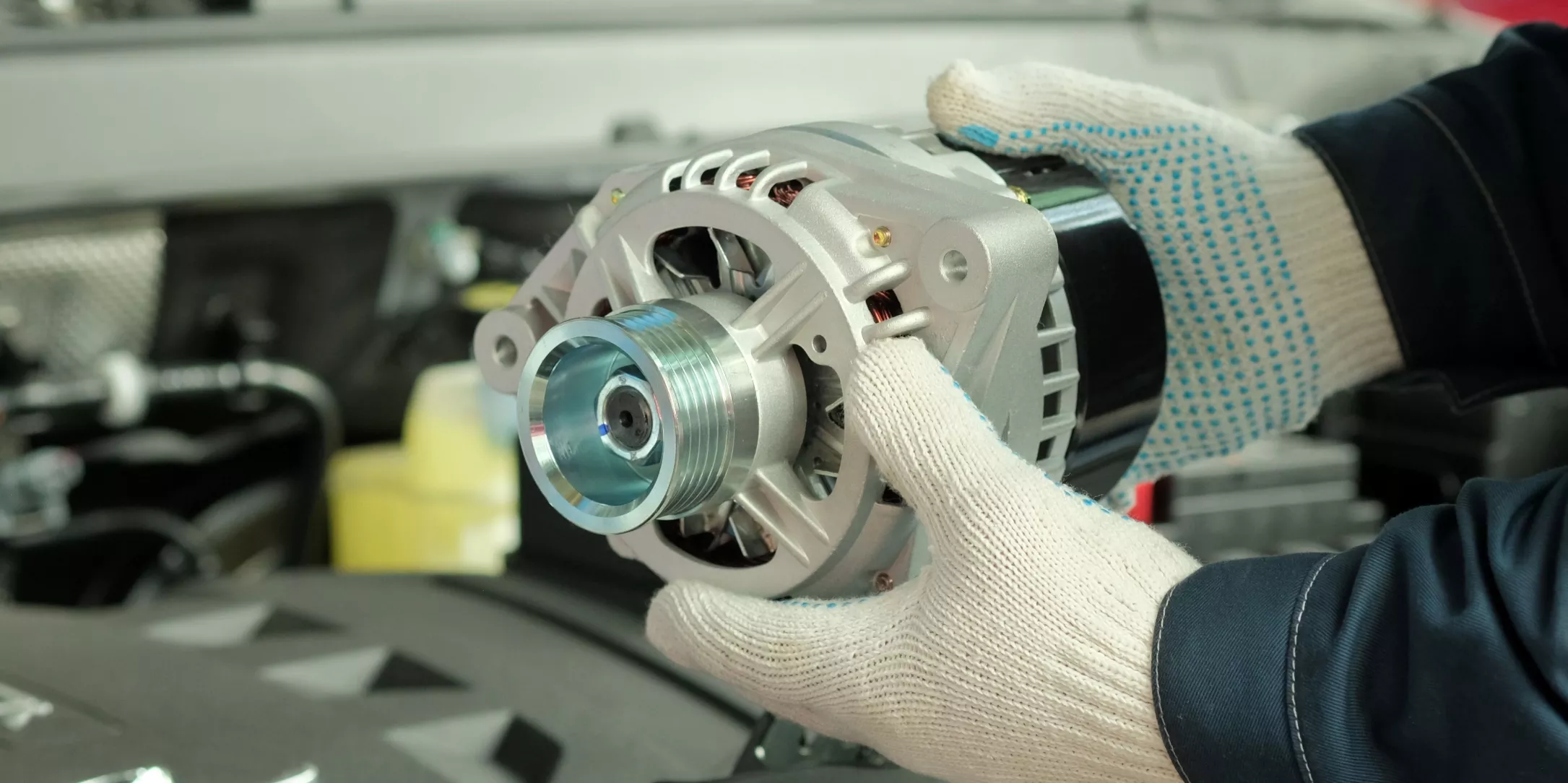

During manufacturing, the first produced part is inspected and approved before line startup. Throughout the process, dimensional and functional checks are performed with precision tools, and all safety-critical features are inspected 100%. Electronic components undergo dedicated testing, while production equipment is regularly calibrated to maintain accuracy.

Validation & Testing

All products are subjected to rigorous durability and performance tests after production. These include assessments under varying temperature, humidity, vibration, and corrosion conditions. Mechanical parts are tested for service life and sealing, while electrical parts undergo electromagnetic compatibility and safety testing. Selective road simulations are also performed to verify real-world performance.

Packaging & Authenticity

To prevent damage during logistics, packaging is qualified to withstand drop, compression, and vibration. Anti corrosion protections and safety caps are applied. Each part carries a unique code or hologram for authenticity with online verification available. Defined palletizing, storage, and transportation conditions ensure secure handling until delivery.

Final Inspection & Shipment Release

Before leaving the facility, every part undergoes final quality inspection. This includes end of line checks and random out of box audits. Once approved, a Certificate of Conformity is issued, and all batch records arecompleted to guarantee full traceability.